History of Electrical Systems and Cables

Insulators Home > Book

Reference Info > History of Electrical Systems and Cables

Information from:

- Dunsheath, Percy. A History of Electrical Power Engineering.

Cambridge, MA (Printed in Great Britain): The M.I.T. Press. Copyright 1962.

LOC TK15.D8.

- Black, Robert Monto. The History of Electric Wires

and Cables. London, England: Peter Peregrinus Ltd (in association

with the Science Museum of London). Copyright 1983. ISBN 0863410014, LOC TK3301.B564.

- McGraw-Hill Book Company. Electrical Maintenance and

Repair: Wiring Diagrams of Electrical Apparatus and Installations.

York, PA: Maple Press. Copyright 1913. LOC TK3205.W6.

- Michael, Donald T (Working Group Chairman). IEEE

Recommended Practice for Electric Power Distribution for Industrial Plants,

5th Edition. New York, NY: Institute of Electrical and Electronics

Engineers, Inc - Standards Board. Copyright 1976. ISBN 0471026867, LOC TK3141.I18.

See the Timeline of Related Developments

for additional information.

This information comes from

- Dunsheath, Percy. A History of Electrical Power Engineering. Cambridge,

MA (Printed in Great Britain): The M.I.T. Press. Copyright 1962. LOC TK15.D8.

The 'Acknowledgements' states:

[...] Illuminations have been generously provided by industrial concerns

as the individual acknowledgements will indicate, and special thanks are due

to the assistance given by Dr. Follett, the Director of the Science Museum,

and his staff, one of whom, Miss Weston, has made many valuable suggestions.

The collection of historical material and confirmation of dates have been

greatly facilitated by the willing help given by the Librarian and Staff of

the Institution of Electrical Engineers. In particular, Mr. H. Lansley has

been tireless in his responses to my many calls on him. Friends in the Supply

Industry have also been most helpful in producing information on early power

stations, much of the information being channelled through Mr. P. A. Lingard

of the London Electricity Board. [...] The many cases of help received from

the light current, heavy current, and instrument sides of the elctrical industry

and from the electrical press are too numerous to permit a mention by name,

but to all I express my most grateful thanks.

The 'Preface' states:

[...] In the introduction to his History of the Institution of Electrical

Engineers, Mr. Rollo Appleyard, writing of the evolution of the Institution

from the former Society of Telegraph Engineers and Electricians, says, "It

has stood at the confluence of the streams of academic and practical knowledge

where for fifty years it has directed and safeguarded electrical progress."

[...] The history of such a subject as electrical engineering does not follow

a simple straightforward list of dates. The contributions of one man may continue

over many decades during which period others pick up the same threads to weave

completely different patterns. [...]

The following information is excerpted from this book.

Origins

[...] It is safe to assume that the first electrical effects to be noticed

by man were the lightning flash and the aurora borealis. Their existence called

for no deliberate act on his part, and they occurred long before he had produced

electrical charges himself, either fortuitously or by design. At first they

and their effects were completely out of man's control, though several thousand

years ago damage to buildings by lightning strokes was prevented by the nature

of their construction. Several famous historic buildings, including the Temple

of Juno and Solomon's Temple, had their roofs covered with metallic points

- sword blades or sharp ornamental objects - with resulting immunity to damage

by lightning. [...]

It was not until the great Benjamin Franklin, American writer, philosopher,

and statesman, became interested in electrical phenomena, that the idea of

deliberate protection of buildings emerged. After his famous and extremely

dangerous experiemnts of collecting electric charges by sending kites up into

thunderclouds, Franklin, in 1750, conceived the idea of a lightning conductor,

and in his Poor Richards Almanac for 1753, he puts forward the proposal

for the protection of buildings 'from mischief by thunder and lightning'.

[...]

The first half of the eighteenth century saw many discoveries and applications

of electricity. Outstandin among these was the principle of conduction and

insulation enunciated by Stephen Grey in 1720. By suspending a hempen line

on silken threads, he transmitted electric charges hundreds of feet. When

metallic wire was substituted for the hempen cord, circuits up to several

miles were made to carry the charge.

The French scientist Dufay seems to have been the first to have established

the idea that electricity appeared in two distinct forms, vitreous

and resinous, the former produced on glass, and certain other materials,

and the latter on amber, silk, paper, etc. He also observed that each repels

its own kind and attracts the other. [...]

The English scientist Dr. Watson made many experiemtns with the Leyden jar,

established the idea of two coatings separated by the dielectric, and spoke

of 'plus' and 'minus' electricity. With others, he also made long circuits

up to several miles, and discharged the Leyden jar through them. [...]

Birth of the Electric Telegraph

[...] The employment of magnetic and electrical effects for the transmission

of intelligence had been predicted long before the advent of the steady current

had provided a sound foundation for practical application. [...]

During the early half of the eighteenth century, a good deal of experimenting

was carried out by Stephen Gray, a Charterhouse pensioner, while Dr. Watson,

a member of a Royal Society Committee, brought to light the essential difference

between conductors and insulators. It was discovered that a damp hempen cord

suspended by silk loops could be made to transmit a static charge from a Leyden

jar. With a metallic wire so supported, the results were still more effective,

and a circuit was set up in July 1747 across the Thames over old Westminster

Bridge. The circuit was completed through the body of an assistant, who held

the far end of the wire in one hand, and with the other touched the water

with a metal rod. His reaction completely vindicated the result which had

been anticipated. Other experiments followed in various parts of London, and

the length of the circuit increased to several thousand feet. Franklin in

1748 in Philadelphia, and De Luc in 1749 in Switzerland, extended the range

but remarkable as it seems today, there was no suggestion of the discoveries

being applied to telegraphy. [...]

A rather fantastic suggestion was made in 1795 by a Spaniard, Salva, who

employed twenty-two pairs of wires for a twenty-two letter alphabet. At the

receiving end, each pair was held by a man who called out his letter when

he felt the shock. In due course, Salva resorted to simpler detectors in the

form of tinfoil plates and reduced the number of wires. [...]

Francis Ronalds moved to the house now known as Kelmscott House in Upper

Mall, Hammersmith, and it was here that he constructed the telegraph system

through which his name became so famous. The best description of his achievement

is contained in a small book which he published in 1823 and reprinted in 1871,

from which it is clear that his first concern was whether the electric fluid

in its static form could be made to travel over long distances without undue

delay. For this purpose, in 1816 he set up two wooden structures in his garden,

twenty yards apart, between which he strung iron wire backwards and forwards,

forming a continuous length of more than eight miles. The wire was insulated

at the 37 hooks on each of the 19 bars at both ends by silken loops, and the

two ends brought out to two pith-ball electrometers. [...]

The event which, more than any other, brought the telegraph to the notice

of the public, was the arrest in 1842 of the murderer Tawell at Paddington

Station. Mr. John Tawell, a respectable resident of Berkhamsted, was known

by the police to be in the habit of visiting a woman, Sarah Hart, at her home

near Slough. Early one morning she was found dead, and a man had been seen

leaving her home in rather suspicious circumstances some time before. On enquiry

at the Great Western station, they learned that a man answering to their description

had just gone off by the slow train to London. "But," said the inspector,

"why not try this new telegraph?" At once the message was sent indicating

that the man wanted was dressed as a Quaker with a brown coat reaching almost

to his feet. There seems ot have been some delay, owing to the fact that the

five-needle instrument had no signal for Q, and KWAKER was not at once understood.

When Tawll stepped out of the train at Paddington, however, he was shadowed

to a New Road omnibus and ultimately arrested. In due course, he was tried

for the murder and executed. The excitement, first over the manner of his

arrest, and secondly through startling revelations of his past career, seems

to have done as much, if not more, for establishing the telegraph of Cooke

and Wheatstone, than all their technical and business ability. Joint stock

companies were set up to exploit the invention for commercial purposes - The

Electric Telegraph company, which paid Cooke and Wheatstone £33,000

for their invention; the Magnetic Telegraph Company, and others - so that

by 1868, over 16,000 miles of telegraph line had been erected. By 1870, the

systems had been incorporated into one national undertaking, and taken over

by the Post Office.

The early lines were crude in the extreme, and the five wires for the Euston-Chalk

Farm circuit were carried in longitudinal grooves cut in the top and sloping

sides of wooden bearers. In consequence, electrical failures were common.

One of these, on the Fenchurch Street - Blackwell line, proved, according

to Fleming, the direct cause of a great improvement in the needle system.

There out of the five wires broke down, and the telegraph clerks devised a

code which enabled them to continue working with only two needles in use.

Finally it was found that one needle was all that was required. When the movement

of the needle was restricted by stops on the dial, a convention of 'dots'

to the left and 'dashes' to the right was adopted, so that various combinations

of dots and dashes gave all the letters and figures required. [...]

Morse was fortunate in enlisting [...] a young man, Alfred Vail, of a mechanical

turn of mind, who not only co-operated in the design and in making equipment,

but, what was even more vital at this time, secured financial backing. On

3 October 1837, Morse obtained his patent, and Vail improved the printer so

that it produced clear dots and dashes. The Morse Code, so well known by the

name of the inventor, seems really to have been the work of Vail, for we read

"Vail tried to compute the relative frequency of all the letters, in

order to arrange his alphabet; but a happy idea enabled him to save his time.

He went to the office of the local newspaper, and found the result he wanted

in the type-cases of the compositors." Thus was established the Morse

Code, which has survived for so long and in so many forms of signalling.

After four years of political string-pulling, frustration, and living on

the verge of starvation, Morse had his system approved by Congress, and he

received an appointment with a salary of $2,500 a month to superintent the

erection of a line connecting Baltimore and Washington. Serious difficulties

arose with underground conductors, but a conductor on poles was carried through,

and on 23 May 1843, messages were transmitted by Morse from the Capitol and

received by Vail at Baltimore. The line was opened on 1 April 1845 as a public

service, and after the Postmaster-General of the day had declined to purchase

the invention for $100,000, Morse proceeded to secure the support of private

enterprise. The Western Union amalgamated some of the earlier participants

in the venture, and went ahead in stretching a network of circuits over the

United States, the most dramatic of which was the New York to San Francisco

line completed in 1861. [...]

Electricity Supply

[...] In the year 1883, an enterprise was started in the West End of London

which, although originally intended as a local private lighting installation,

ultimately developed into an outstanding example of public electricity supply,

and one of great technical and engineering interest. As such, the Grosvenor

Gallery installation in New Bond Street will always rank as a pioneer in public

supply systems. [...] The lighting of the gallery was by arc lamps on a series

circuit with an automatic regulator maintaining a steady current of ten amperes,

and gave such satisfaction that requests for supply soon began to come in

from neighbouring residents and shopkeepers. Under a new Act, the Grosvenor

Gallery Company sought and obtained the permission of the local Authority

to run overhead lines across the roofs of houses, carrying the high tension

current. Each consumer was provided with a small transformer, the primary

windings of several being connected in series on the 2,000-volt supply circuit.

THe voltage was later raised to 2,400. [...]

Within a very few months, the system stretched from the Thames to Regents

Park, and from Knightsbridge to the Law Courts. Hundreds of iron posts fixed

on the roofs of houses carried rubber insulated conductors supported on steel

suspension wires by leather thongs. [...]

The release of capital by the 1888 Amending Act resulted in the inauguration

of many new supply systems both in London and in the Provinces. By the end

of the century, there were something like thirty power stations in London

alone, under the control of sixteen undertakings, most of them private companies.

[...] Having no power to open up the streets for underground mains, [companies]

carried their distribution circuits on overhead lines erected over the roofs

of houses. [...]

Alternating Current

The phenomenal growth of electrical engineering during the last two decades

of the nineteenth century, which had followed the introduction of the incandescent

lamp, left the supply industry in a curious state of uncertainty on an important

and much debated issue. [...] Namely, should the current, when generated mechanically,

be continuous or alternating? The experts, ranging themselves into two opposing

camps, debated the question hotly for many years. As we know today, the exponents

of the alternating system ultimately held the field, and development followed

this course. The direct current enthusiasts, however, made such progress over

the years in carrying their ideas into effect that even now (1960), over half

a century later, there are still vestiges of D.C. sections remaining, though

they are rapidly approaching extinction. [...]

The direct current engineers, from the very beginning, appreciated that the

extension of a system beyond the immediate surroundings of the generating

station raised the question of economy in cost of the mains and the control

of the drop in voltage at the end of long sections with increasing load. They

saw that to overcome this difficulty, they would have to raise the voltage

beyond that at which the consumers' lamps would be connected, and Crompton,

Hammond, and others introduced three, four, and even five-wire systems whereby

the dynamos on a 100-volt system could generate at 200, 300, or 400 volts.

[...] Double-wound dynamos with the separate windings brought to two separate

commutators were supplied at the high voltage side direct from the central

station, and gave the consumers' voltage on the second commutators. High voltage

D.C. transmission with voltages up to 1,500 was installed in this way at Chelsea

(1889) and Lambeth (1896), and at several provincial towns from 1884 onwards.

[...]

The Paddington scheme installed for the Great Western Railway by the Telegraph

Construction and Maintenance Company provided for 4,100 incandescent lamps

and 100 arc lamps, and covered an area of some 70 acres. This installation

had gone into operation on 21 April 1886, and was destined to give satisfactory

service for twenty years. [...]

As J. E. H. Gordon's installation [at Paddington] ran satisfactorily until

1907, when it was superseded by a completely new power system at Park Royal,

it may be considered as a landmark in the development of alternating current,

although he himself lost faith in A.C. and immediately joined the newly formed

Whitehall Electric Supply Co., registered in 1887 with a capital of £200,000,

to design and install a direct current station at Whitehall Court. [...]

As such voltages with alternating current on this scale were new and their

practicability uncertain, Ferranti built an experimental transformer to step

up the 2,400 volts at Grosvenor Gallery to 10,000, and gave a public demonstration.

There were, of course, no suitable instruments for measuring such a voltage,

but he connected a hundred 100-volt lamps in series, and showed that it was

a feasible proposition. [...]

So far as the transmission of the current to London was concerned, the amended

Lighting Act of 1888 posed certain practical problems. For instance, to open

up streets over the distance of nearly five miles would involve many local

authorities whose consent might be difficult to obtain or would at least result

in delays and extra cost. The railways, on the other hand, were run on private

property and soon provided the required rights of way for carrying the high

voltage cables to London and across the bridges to Charing Cross, Cannon Street,

and Blackfriars. [...]

The earliest example of three-phase generation and transmission in Britain

was in the Wood Lane station, constructed as a joint enterprise by the Kensington

Court and Notting Hill Companies, and put into operation in October 1900.

The designers wished to adopt a voltage of 6,600 volts, but in spite of the

existence of the Deptford 10,000-volt single-phase system, the authorities

would only sanction 5,000 volts, and the system ran at this voltage for nearly

forty years, when it was raised to 6,600 volts in accordance with other systems.

[...]

Power and Traction

Much ingenuity was displayed in the method of carrying current to the moving

tramcar. The overhead trolley-wire was an obvious engineering solution, but

although it was employed in 1883 at Portrush in Ireland and at Richmond in

Virginia, opposition arose in other and older towns. Boston, Massachusetts

was able to take 9,000 horses off the streets, but opposed the unsightly trolley

wire. The result was that several alternative systems were tried out. [...]

Neither system survived, however, and the overhead trolley wire operating

at about 600 volts became standard practice. The return circuit was usually

along the bonded running rail, though double-trolley wires were used at times

to prevent interference. [...]

Considering the choice between A.C. and D.C. in the motor field, it is not

surprising that in the development of electric traction, what might almost

be styled a second 'battle of the systems' should have been fought. Indeed,

it still continues, for countries even take sides in the battle between A.C.

and D.C. traction, and in this country the choice has several times been the

subject of public inquiry.

Electric traction first appeared in Britain on 3 August 1883, when a quarter-mile

length of railway was opened for traffic at Brighton by Magnus Volk. The current

was supplised from a third rail at 140 volts D.C. A few weeks later, the famous

Portrush line in Northern Ireland began to operate at 550 volts D.C., carried

by an overhead trolley wire. [...]

In 1890, the City and South London tube was opened, employing electric locomotives,

and the Cnetral London tube between the Bank and Shepherd's Bush followed

within a few years. Both were D.C. systems at 500 volts, supplied from a third

rail.

The City and South London system saw the first application of direct drive

from the motors on to the wheel axles. [...] The current at 500 volts was

supplied through a third rail of steel channel, supported on glass insulators

from transverse wooden sleepers, and picked up by cast iron slippers. [...]

Other sections of electrified track appeared: Bow to Upminster in 1905, Paddington

to Westbourne Park in 1906, Lancaster to Heysham in 1908. The London ones,

influenced no doubt by the underground examples, kept to D.C., but for the

Heysham line, single-phase 6.6 kV at 25 cycles, carried on an overhead trolley

wire, was adopted.

Wide differences of opinion arose at to voltage and system, and from 1916,

1500 volts D.C. on an overhead wire became increasingly popular. [...] In

1956, the Transportation Commission decided on a 25 kV 50 cycles single-phase

system as national standard. [...]

On the A.C. side, different practices developed in different countries. In

1930, for instance, the three-phase system disappeared finally from the Swiss

Federal Railways, and was replaced by single-phase 15,000-volt current at

a frequency of 16 2/3 cycles per second. About the same time, there was one

scheme in the United States employing 11,000 volts at 25 cycles on the trolley

line, with 300 h.p. A.C. motor, and another operating at 3,000 volts D.C.

[...]

The Turbine Era

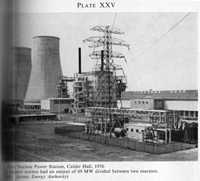

[...] Between the two world wars, the great reorganization of the electric

supply industry in this country [Britain], which led to the construction of

the 'grid', was formulated and carreid out. In 1917, a government committee

recommended that all supply undertakings should be brought under one central

authority, and in 1919 the Electricity Supply Act set up the Electrical Commissioners,

who started work in 1920. Districts were organized under the title Joint Electricity

Authority, but were often under suspicion from the undertakings and were not

completely effective, so that in 1925, reconsideration of the situation by

the Weir Committee led to the formation of the Central Electricity Board.

Its main functions were the construction of a nation-wide transmission network,

the adoption of selected generating stations, and the standardization of frequency.

At the time, there were 17 different frequencies in use, and 80 undertakings

operating on other than 50 cycles.

This development was embodied in the important 1926 Electricity Supply Act,

and the now well-known steel transmission towers soon began to appear. A standard

transmission voltage of 132,000 volts was adopted, and the three-phase circuits

were designed to carry 50,000 kVA on steel-coated aluminium conductors 0.77

in. in diameter, having the equivalent copper section of 0.175 sq. in. The

towers were designed for single and double three-phase circuits. In explaining

in 1927 the eight-year programme for constructing the Grid, Sir Archibald

Page said, "The Grid will go a long way towards ensuring the universal

availability of electric power throughout the country. It will bring the cost

of production in the majority of supply undertakings down to the figure which

has been attained by the few in whose areas electricity is already cheap and

abundant. [...]

The continued expansion of the grid and the increased scale on which current

is generated and distributed, has naturally had considerable influence on

the development of both transformers and switchgear. Larger and larger transformers

have been constructed. One example is the 110,000 kVA at Battersea B, first

installed for 80,000 kVA and modified for the higher output which converts

from 11,000 volts to 66,000, and has forced oil cooling. Another is the 75,000

kVA transformer at Dalmarnoch, which is air cooled, while at Barking there

are two, each of 93,750 kVA capacity. During the past few months, a British

transformer of 200,000 kVA has been supplied to the United States. Tappings

on the windings of high voltage transformers for voltage adjustment on load

have developed rapidly and are now in common use. Protection of transformers

against damage through system surges becomes increasingly important on large

networks, and this has resulted in much greater reinforcing of end turns to

withstand steep wave fronts. But possibly the most spectacular improvement

in the modern transformer is in the efficiency achieved. Values of 99 per

cent are now cmmon, and in the very large sizes 99.5 per cent is frequently

achieved. [...]

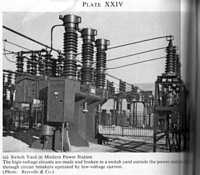

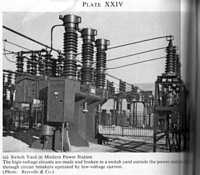

The function of opening and closing a circuit for the purpose of normal control

has usually been separated from that of opening the circuit in an emergency

brought about by short-circuit or overload. In this case, the situation has

usually been met by inserting a fusible link or cut-out in the circuit. As

loads increased, however, the two fucntions were combined in one device known

as a circuit breaker, in which a main switch was released by an electromagnetic

trip. The range of equipment thus stretches from the simple tumbler or press-button

switch with a separate simple wire fuse, to the high-voltage oil-filled or

air-blast circuit breaker in the switch yard of a large power station.

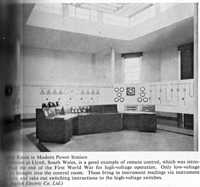

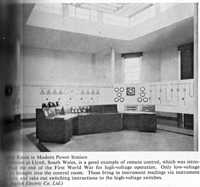

The first power stations were controlled by open knife switches on slate

or marble panel switchboards, and as currents grew in magnitude, circuit breakers

with magnetic blowouts to extinguish the arc were added. Well before 1900,

the switchboard had taken its place as a vital component of a power station,

and improvements were introduced both into the arrangement of circuits and

the design of individual switches to reduce the risk of failure and to ensure

the continuity of supply. A major modification was in the adoption of the

dead front, in which no live metal was accessible, a condition which became

essential on the adoption of alternating current and higher voltages. At one

stage in this development, remote mechanical control of the switches was resorted

to, the switches themselves being housed in brickwork cubicles a short distance

behind the control board. [...]

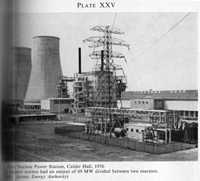

About 1940, it became evident that from a national point of view, the continued

expansion of the British grid required a still higher voltage than 132,000,

and in 1952 the Electricity Authority started on the construction of a super

grid to operate at 275,000 volts. The two main objects were to interconnect

the major groups of generating stations, and to connect new generating plant

located on the coalfields to bulk supply points in areas where there was a

deficiency of fuel. In addition, the superimposed grid would provide additional

safeguards in times of breakdown or other emergency, and so make possible

an appreciable reduction in the provision of standby plant. One line of towers

on this super grid can carry over 500,000 kW on each of two circuits, and

already a considerable part of the scheme is in operation.

[...]

The Early Telephone

[...] Early in 1877, the telephone had created a world-wide interest. Speech

had been transmitted over the existing telegraph lines, and the time had come

for commercializing hte invention. Bell offered pairs of instruments on lease

'for social purposes' at $20 a year, and 'for business purposes' at twice

this rent. Very soon the instruments were being produced in a small factory

in Boston, Massachusetts, and supplied over a wide area, including New York

and London, where Bell read a paper before the Society of Telegraph Engineers.

[...]

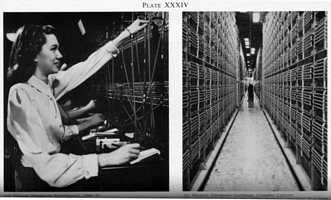

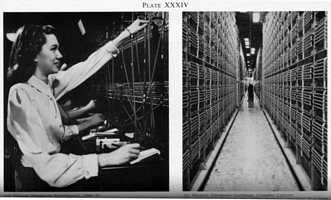

The idea of a central switchroom by which subscribers could be interconnected

was suggested in Octber 1877 by an enterprising journalist in Boston, and

quickly took practical shape based on the telegraph system which had already

operated to a limited extent in the United States, England, and France. At

first a ticket system enabled an operator to receive requests from individual

subscribers for a specified line between certain times, and to issue instructions

by means of a ticket to another operator, who inserted and withdrew plugs

as required.

The first telephone exchange on a commercial basis was installed at New Haven,

Connecticut in January 1878. Drop indicators were used with a call bell and

two-way lever switches enabled the operator to connect his own telephone to

any line and obtain instruction. Another switch enabled him to send out a

signal in the form of a loud buzzing sound on the subscriber's receiver. A

few months later, an exchange in which cords were used was set up in Chicago.

The subscribers' indicators were arranged along a wall, and a series of horizontal

metallic rods grouped in pairs as connecting racks. These had clearing-out

drop indicators associated with them. [...]

The first telephone exchange in England was established by the Telephone

Co., Ltd., at 36 Coleman Street, E.C., in August 1879. [...]

In 1880, the instruments standardized for subscribers' use were Telephone

No. 1 and Telephone No. 2. The former, the wall type, was made of wood, having

a projecting ebonite mouthpiece on the transmitter, with a tubular receiver

and switch hook at the side, and a double magneto bell in front. The desk

type, constructed mostly of metal, carried the transmitter with its ebonite

mouthpiece on a tubular pillar with the receiver and switch hook on the side,

but the bell was accommodated in a separate wooden box. [...]

In 1896, the major trunk lines of the National Telephone Co. were purchased

by the Post Office, and at the turn of the century, common battery (CB) working

was introduced. Many inventors and many committees contributed on both sides

of the Atlantic to this important innovation. In the famous Hayes circuit,

based on a patent granted in 1892, the subscriber received current from a

large common battery locaed in the exchange and singalled by lifting his receiver

from a switch hook. [...]

When the first telephone exchanges were projected, the telegraph system with

its ramification of circuits was already established, and it was natural that

practice should follow precedent. There was, however, a basic difference in

the requirements of the two services; telegraphs were usually long-distance

circuits with lines from town to town, whereas in telephony, initially at

any rate, the main problem was to connect many subscribers in a congested

urban area with one another through a local exchange. Consequently, bare wires

strung over rooftops became the usual practice. Baldwin has given an excellent

description of the early history of overhead telephone line plant, in which

he traces the development from the practice of the telegraph engineer.

Telegraph exchanges were conveniently housed in high buildings surmounted

by a derrick from which lines radiated in all directions. The most commonly

used wire to start with was bare galvanized iron, No. 12 gauge, with other

sizes depending on the whim of the particular engineer. To prevent corrosion

in industrial towns and large cities, the wires were often protected with

an impregnated cotton covering. Although the high electrical resistance of

iron wire was a great disadvantage, it required many years of testing and

consideration before its place was taken by copper. Because of their increased

tensile strength, phosphor bronze and silicon bronze were favoured by some,

but hard-drawn copper held the field until the brittleness of bronze was overcome.

Soft copper binding wires were introduced for holding the wire to the insulator

of porcelain of various shapes, and gutta-percha covered wire was used for

leading into premises. By 1890, silicon bronze had been so much improved that

it had been brought into general use for subscribers' circuits throughout

Britain in a standard weight of 40 lb. per mile.

The congestion resulting from the large number of wires leaving the structure

over an urban telephone exchange soon called for a bunching of the circuits

into groups, and this was done by the use of multi-core aerial cables. Early

forms consisted of a number of gutta-percha insulated wires, bound together

with tape, and associated with a stranded galvanised wire to give supporting

strength. Later, rubber was substituted for gutta-percha, which cracked when

exposed to air and sunlight. This also enabled more conductors to be accomodated

in a cable of the same weight, and standard types were adopted with 26 and

52 pairs. As an example of the magnitude of the task of getting the circuits

away from an early telephone exchange, the case of Sheffield may be cited.

There, the angle iron derrick erected in 1891 accommodated over 1,000 wires.

A problem which faced the early telephone engineer was the prevention of

overhearind between circuits, when so many had to be carried in close proximity

to one another. The impracticability of the single-wire earth circuit which

had been suitable for telegraphs was soon appreciated, and in 1892, expensive

schemes of doubling, or making the circuit 'metallic' as it was called, were

carried out. Even then, induction effects were found to be serious, and twists

were introduced. The credit for this idea goes to Professor Hughes, who referred

at a dinner of the National Telephone Co. in 1895 to his paper in which he

had first announced the idea. For long-distance overhead liens, then growing

rapidly along the main roads of Britain, the system of twisting a pair between

poles and of inserting crosses, was adopted extensively. [...]

The heavy overhead long-distance lines continued to grow in number and size

until the First World War but, as even then they failed to meet the demand,

more and more cables were laid. For subscribers' lines, 1,000-pair cables

with 6 1/2 pound conductors became common. [...]

When Sir William Preece visited the Philadelphian Electrical Exhibition in

1884, the number of telephone stations in the United Kingdom was already 11,000.

He found that the comparative figure for the United States was 148,000. He

explained the discrepancy to his hosts on the grounds that in London an errand

boy cost 2s. 6d. a week, whereas a similar service in New York cost 12s. to

15s. It paid to use the telephone. Today (1960), there are still about nine

times as many telephones in the United States as there are in the United Kingdom.

[...]

Science in Telecommunication

[...] Michael Idvorsky Pupin [...] spent some time studying at Cambridge

and Berlin Universities, [then] returning to Columbia [University], where

he was appointed to a chair. It was here that during twenty-five years he

made his inventions, the most significant of which, the Pupin Coil, brought

him in $1,000,000. The patent was bought by the American Telephone and Telegraph

Co.

Thus was laid the foundation stone of 'loading' an electrical transmission

line, and the first practical application was in August 1902 when loading

coils were inserted in a ten-mile length of telephone cable between New York

and Newark, New Jersey. By this modification, the grade of transmission was

improved to that obtainable on a five-mile length of unloaded cable. [...]

In the long-distance circuits in England, open lines carried on poles had

been strengthened by increasing the size of the copper conductors. In 1895,

the limit was reached on the Longon-Leeds-Edinburgh line, when conductors

weighing 800 lb. per mile were erected. [...]

After the successful pupinization of the New York-Washington and New York-Boston

lines, the American Telephone and Telegraph Co naturally turned its attention

to transcontinental possibilities and, by loading and reinforcing overhead

lines, a New York-Denver circuit of 2,200 miles was achieved as a first stage.

On 25 January 1915, a commercial telephone service was inaugurated between

New York and San Francisco, a distance of 3,400 miles over open wires weighting

870 lb. per mile. Today the United States has a vast system comprising some

200 million miles of wire, and practically any two telephones can be interconnected

on demand. [...]

Two-wire amplified circuits were at first developed for inland trunk cables

in this country, but by 1939 had been replaced by four-wire circuits with

losses reduced to practically zero. Not only had the repeater reduced the

need for capacity correction in the line by the addition of inductance, but

carrier technique, introduced in 1920, had made it possible to transmit more

than one conversation over one pair of wires. [...]

By 1937, this new tool had made it possible to carry twelve channels on each

pair of a cable. [...]

Measurement Instruments and Standards

[...] At the International Electrical Exposition held in Paris in 1881, much

dissatisfaction with the position was expressed by practical electrical engineers,

who were still using widely 'Weber' to denote the unit of current, measuring

electrical pressure in terms of the equivalent number of Daniell cells, and

resistance in terms of miles of telegraph wire; and the new names ampere,

volt, and ohm were adopted. [...]

Professional Organizations

[...] For many years before the formation of a professional body for electrical

engineering, the pioneers who were laying the basis of the science found a

suitable forum in the Royal Society. Many fundamental communications on electrical

engineering by Sturgeon, Kelvin, Wheatstone, Hopkinson, and others have appeared

in its Transactions.

During the second half of the eighteenth century, small societies were founded

by groups of men itnerested more in the development of engineering and technology

than in pure science. The Lunar Society, so called because the meetings were

arranged at the time of full moon in order that the members could find their

way home easily, included many well-known pioneers whose names became famous

- Watt, Boulton, Murdock, Priestley, and others. [...]

In 1872, The Telegraphic Journal and Electrical Review was launched,

and continued for twenty years when, under Alabaster Gatehouse and Kempe,

it became The Electrical Review, aiming rather more at the commercial

than the academic side of electrical engineering. Later, in 1891, Lightning

appeared under the control of Robert Hammond, who also served as honorary

treasurer of the Institution for many years. One of the interesting features

of Lightning was the publication of statistics of the industry; subsequently,

under the direction of R. W. Hughman, it changed its title to The Electrical

Times and has made a considerable impact. [...]

English Social and Historical Background

[...] Soon after its introduction, the telephone assumed an important position

in the commercial world. In 1889, the trhree principal companies which had

carried through the pioneer work were amalgamated to form the National Telephone

Company, with some 28,000 lines. From 1892, the Post Office came into the

telephone field, and in 1896 all trunk lines came within official control.

The final stage in the development came in 1911, when the Post Office took

over the whole telephone system of Britain. [...]

Chronological Table

[very selected excerpts]

1837 - Cooke and Wheatstone first practical electric telegraph, on L. &

N.W. Railway, London - Camden Town

1856 - Formation of Atlantic Telegraph Company.

1871 - Society of Telegraph Engineers (later I.E.E.) founded.

1873 - Gramme first transmitted electric power over three-quarters of a mile,

at Vienna Exhibition.

1877 - Edison Electric Light Co. formed.

1880 - Society of Telegraph Engineers added 'and Electricians' to its title.

1881 - Edison constructed his first electric power station at Pearl St. N.Y.

1882 - Gaulard and Gibbs arranged transformer in series.

1882 - Tentative electric tramway at Leytonstone, London.

1882 - 35 mile 200 volt A.C. transmission at Munich.

1883 - Step down transformers come into use.

1883 - Charing Cross Electric Supply Company formed.

1889 - Formation of National Telephone Co.

1889 - General Electric Co. formed in England.

1895 - Rotary automatic telephone exchange switch introduced.

1897 - Brown invented oil-immersed circuit breaker.

1900 - Central London Railway opened.

1900 - First public 6,600 volt 3-phase supply, at Newcastle.

1905 - Niagara Falls 60,000 volt transmission over 200 miles.

1905 - First power station system control room in Great Britain at Carville.

1906 - Hewlett introduced high-voltage suspension insulator.

1920 - Emanueli introduced oil-filled cable.

1925 - Barking Power Station opened by King George V.

1929 - First section of the British 132 kV grid operating.

1929 - A.C. Multiplex 12 Channel telegraph system in operation.

1942 - British Electricity Authority planned 275 kV grid.

1946 - Central Electricity Authority connected 180 electricity compaies,

354 municipal undertakings, and 9 joint electricity authorities.

1959 - Kariba hydro-electric shceme on Zambesi, with 100 MW sets and 330

kV lines working.

1961 - Membership of Institution of Electrical Engineers exceeds 48,000.

Illustration Plates

This information comes from

- Black, Robert Monto. The History of Electric Wires and Cables.

London, England: Peter Peregrinus Ltd (in association with the Science Museum

of London). Copyright 1983. ISBN 0863410014, LOC TK3301.B564.

The 'Foreword' by John Banks states:

Industrial history, especially in its most specialised areas, does not always

get the support of the industrialist. As one of the latter and also a professional

engineer, I have an ingrained desire to keep records, but this does not ensure

that the kind of record provided in this book will result. For that we have

to rely on the enthusiasm, almost fanaticism, of the energetic story teller

which Robert Black obviously is. [...] This sustained effort has enabled him

to write a most comprehensive book, ranging from early telegraph cables to

the most recent specialised types of cables such as are required for ships

and aircraft. [...]

The 'Preface' states:

The story of the gradual evolution of electric wires and cables, from those

used in the early experiments in electrostatic telegraphy to such modern examples

as supertension power cables and optical fibre telecommunication cables, is

a fascinating one with its full share of drama and suspense. [...] In the

chapters which follow, an account is given of the development of the principal

types of electric wires and cables, from the earliest times up until about

halfway through the present century. The treatment varies in texture and cannot

claim to be comprehensive, for each cable installation is a story in itself

and availability of space has necessitated selection. Despite this and a confessed

parochial interest in two among the many great cable makers that have flourished

during the period (Callendars and the B.I. Company, by whose decendant BICC

I have been employed for nearly forty years), it is hoped that the reader

will share in the fascination and pleasure that building up a cable collection

and compiling its history has brought. [...] It was Jim Temple Hazell who

first encouraged my interest in the subject, and helped the start of a collection

of cables by passing over the duplicate samples from the Hunter-Hazell Collection,

now in the Science Museum. [...] The author's thanks are due to Mr. John Banks,

Managing Director Group Services, BICC plc., President of the Institution

of Electrical Engineers, for permission to proceed with the writing of this

history and for providing a Foreword, to his colleagues at Wood Lane for encouragement

and advice, and particularly to his fellow library staff, who have suffered

from a plethora of cable samples and documents without complaint for a long

while. [...]

The 'Acknowledgements' states:

Diagrams and photographs are reproduced by kind permission of the following:

Ferranti Limited (3.2)

Pirelli General Cable Works Limited (9.1)

British Patent Specificication No. 933 of 1851 (5.1)

US Patent Specification 304/539 of 1884 (5.2)

All others, unless otherwise stated, by permission of BICC plc.

The following information is excerpted from this book.

Early Telegraph Cables

In the early years of the eighteenth century, many natural philosophers experimented

with electricity, with a view to establishing its applications. Among these

was one Stephen Gray, F.R.S., described as a Charterhouse Pensioner, who demonstrated

the principles of conduction and insulation in 1730 by suspending a damp hempen

line on silk threads. He found that he was able to transmit electrostatic

charges for distances of up to several hundred feet. When metallic wire was

substituted for the damp hempen cord, the charge could be carried over circuits

several miles long.

Six years later, John Woods improved on the system, and in 1747, Sir William

Watson, F.R.S. constructed a two-mile line with an earth return. This circuit

was set up in the July of that year, and was routed across the River Thames

by way of the old Westminster Bridge. In order to demonstrate the effectiveness

of the circuit, Sir William completed it through the body of an assistant,

who held the far end of the wire in one hand, and with the other touched the

water with a metal rod. It was reported that his reaction to the static discharge

from a Leyden Jar "completely vindicated the result which had been anticipated".

An interesting development and the first recorded account of the use of paper

as an electrical insulating material, was given in a paper presented by Don

Francisco Salva (1751-1828) to the Academy of Science in Barcelona in December

1795. In describing his experiments in telegraphy to the Academy, he also

suggested the possibility of underground transmission by cable:

"...it appears, little short of impossible to erect and maintain so

many wires" (with the electrostatic telegraph system that he was contemplating,

Salva would require 22 wires, one for each of the 22 letters of the telegraph

alphabet) "for even with the loftiest and most inaccessible supports,

boys will manage to injure them, but as it is not necessary to keep them very

far apart, they can be rolled together in one strong cable, and placed at

a great height. In the first trials made with a cable of this kind, I covered

each wire with paper, coated with pitch or some other ideoelectric substance,

then tying them together, I bound the whole with more paper, which eventually

prevented any lateral escape of the electricity. In practice, the wire cable

could be laid in subterranean tubes, which for greater insulation, should

be covered with one or two coats of resin."

This grand concept resulted in the laying down of a 26-mile long telegraph

line between Madrid and Aranjuex. By means of electrostatic charges, Don Salva

managed to transmit effective signals over it. Any underground section would

no doubt be out of sight, if not out of reach, of the boys! [...]

Francis Ronalds had set up an eight-mile telegraph circuit in the garden

of his home in Hammersmith, now known as Kelmscott House in the Uppoer Mall.

The telegraph was described in some detail in a small book, published in 1823

and entitled Description of an Electric Telegraph and of some other Electrical

Apparatus. From this it is clear that Ronalds' main interest was to establish

whether the electric fluid in its static form could be made to travel over

long distances without undue delay. For this purpose, he set up two wooden

frames twenty yards apart, between which he strung wire backwards and forwards

to form a continuous length of just under eight miles. THe wire passed through

loops of silk at each of the 37 hooks on the 19 bars on the two frames. The

two ends of the wire were attached to pith ball electrometers. "When

the line was charged by connection to a Leyden jar, the electrometers at the

near and far ends diverged at exactly the same moment, and on discharge by

being touched by the hand, collapsed simultaneously." [...]

[William] Cooke made contact with the Directors of the Company [of the London

and Birmingham Railway] and with their engineer Robert Stephenson, initially

with the object of interesting them in a fire alarm system based upon his

mechanical telegraph and an alarm bell, which he demonstrated to them on 4th

July, 1837. They were, however, interested in a means of signalling between

Euston and Camden Town, with the object of informing the men operating the

winding engine when the train was ready to start.

A further demonstration was arranged for the 9th July, when message sending

over a distance was demonstrated to Robert Stephenson and to Robert Creed,

the Company Secretary. For this second experiment, Wheatstone had set up a

"hastily made telegraph" employing four needles and four wires.

The onlookers were impressed, and expressed the wish for the system to be

demonstrated over a still greater distance. Accordingly, an extended line

was prepared [by Charles Wheatstone] over the route from Euston to Camden

Town.

It is known that the installation of telegraph wires over this route included

a section at least of the second of the conductor systems described in the

patent of 1837: "The long extensions of conducting wires, which may be

called telegraph wires, may be lodged in channels formed in wood rails and

lines with any suitable resinous matter, with a covering rail of wood over

the channels to protect the wires from injury and from damp.... Another form

of rail containing distinct channels for the several wires, each of which

channels is closed by a fillet of wood driven into it. Such rails may be laid

underground when that is more convenient than to place them above ground on

posts, and some parts of a long line may be under ground and other parts above

ground, and extend along the sides of public roads or railways or otherwise,

as is most convenient and suitable to go from one terminus to the other."

As depicted in the patent, the five copper wires were laid in long wooden

baulks of trapezoidal cross section, the grooves being plugged with wooden

strips and the baulk finally painted with a preservative tar compound (Fig.

1.1). The buried section of the line, in the form of these baulks, was laid

in a trench alongside the railway track. The trench was filled in with pitch.

The length of the section so buried was just under two miles. [...]

The telegraph was a success. The wood baulk conductor array functioned satisfactorily,

despite the fact as may be seen in the lengths that have survived, that the

conductors used were not insulated in any specific way other than by the timber

and its preservative tar compund. In the original specification, it was suggested

that, if necessary, the wires could be covered with thread and varnished.

[...]

The Grosvenor Gallery and Deptford

In retrospect, the year 1871 was an important one for the electric cable

industry, if such it could be called at that time, bearing in mind its preoccupation

with telegraph cables, for it was in this year that Zénobe Gramme (1826-1901)

perfected the ring dynamo and a really satisfactory source of electric power

became available. [...] The use of arc lamps spread rapidly, particularly

with the development of the improved version of the lamp by Paul Jablochkoff.

In 1878, these improved lamps, known as Jablochkoff Candles, were used in

London for the lightning of the West India Dock, Billingsgate Market, Holborn

Viaduct, and parts of the Thames Embankment.

In general, very little is known of the type of cable employed in these installations.

Often, earth returns were used in conjunction with a plain copper wire supported

on some form of insulator. [...]

It was not until 1911 that a really tough outer sheath was developed for

application to rubber cables. This was done by the St. Helens Cable and Rubber

Company of Warrington, who, in addition to their cable making activities,

had been manufacturing solid rubber tyring by an extrusion process, for the

wheels of horse-drawn vehicles, particularly Hansom cabs. From this was derived

the term 'cab-tyre' sheathing. Designed to be "of great mechanical strength,

water and corrosion proof, flexible, smooth, and 'un-kinkable' ", it

was ideally suited for the protective sheathing of cables for such arduous

duties as might be experienced in collieries.

In 1886, the India Rubber and Gutta Percha Company produced a cable consisting

of a 19/15 gauge tinned copper conductor, insulated with 0.21 in. of pure

and vulcanized India rubber, with a double jute braiding as an outer covering.

The cable was designed to operate at 2400 volts single phase a.c. This cable

was to be used in the now famous Grosvenor Gallery installation. [...]

It all began with the Paris Exhibition of 1882, at which the newly exploited

electric light played an important part among the exhibits. The Earl of Crawford,

one of the Commissioners appointed by the British Government to visit the

Exhibition and report back on the latest developments, on his return suggested

to Sir Coutts Lindsay, who was the proprietor of the fashionable Grosvenor

Art Gallery in Bond Street, that he should install electric light in the Gallery.

Sir Coutts agreed, and in early 1883 a pair of Marshall's semi-portable engines

were erected in an out-building behind the Gallery. These were belted to a

couple of separately excited Seimen's alternators, generating single phase

current at 2000 volts. The plant supplied arc lights in series, and an automatic

regulator kept the line current constant at 10 amperes. [...]

Interest in the plant soon spread among the local shopkeepers and residents,

and requests for supplies of electricity were met initially by installing

individual transformers, or secondary generators as they were then called,

in the house of each consumer. The primaries of all the transformers were

connected in series with the line, in accordance with the system then recently

introduced by Gaulard and Gibbs. The high tension current was transmitted

by overhead cables supported from poles on the house tops. This overhead system

had the advantage that despite the restrictive provisions of the 1882 Electric

Lighting Act, nothing was involved in obtaining permission for the installation

than the consent of the house-holders and of the vestries concerned. [...]

The result of all this was that the small installation very soon became seriously

overloaded. It was decided therefore to establish a permanent generating station

under the Gallery, and on a considerably larger scale. The necessary construction

work commenced on December 1884. [...]

Sir Coutts Lindsay then joined the Earl of Crawford and Lord Wantage in forming

a small private company, to be called Sir Coutts Lindsay and Company Limited,

but which was more famously known as the 'Grosvenor Gallery Electric Lighting

Works' or as 'The Grosvenor Gallery Company'.

The new station went into service towards the end of 1885. [...] From the

start, a great deal of trouble was experienced, and indeed the installation

proved practically unworkable. Numerous complaints were received, arising

from poor regulation, loss of supply, overloading, and breakdowns, until the

situation fast was becoming desperate. [...]

On the 13th January, 1886, the Directors appointed [Samuel] de Ferranti [as]

Chief Engineer of the Company, to be in full charge of the station. In the

space of a few months, Ferranti managed to carry out a complete overhaul of

the system. The overhead network was re-modelled for parallel working, transformers

to his own design were installed in place of the Gaulard and Gibbs series

devices, the voltage was increased to 2400 volts by connecting the windings

of the Siemen's alternators in series instead of in parallel (each alternator

had two sets of 1200 volt windings), and new switchgear was designed and erected.

The vulcanized India rubber cable used for the overhead supply network was

that supplied by the India Rubber and Gutta Percha Company (Fig. 3.2), and

was suspended by leather thongs from a steel catenary wire which ran between

suitable iron masts erected on convenient roof tops and a lattice tower on

the roof of the Gallery itself. Two cables, spaced 12 inches apart, were used

in each connection, being shackled off at the masts. The cable was supported

in Johnson and Phillip's 'fluid type insulators'. By 1888, the system had

grown to the extent that some four hundred premises were being supplied with

electricity.

[...] So successful were the new arrangements, that customers who had been

infuriated by the repeated breakdowns which had occurred with the earlier

system, had their confidence restored, and the demand for new installations

increased rapidly. The Directors decided to form a new company to take over

the station, and to extend operations in accordance with some ambitious plans

that had been proposed by their Chief Engineer. These were concerned with

the setting up of a remote generating station to supply electricity to London

on a really large scale. The new company, The London Electric Supply Corporation

Limited, was registered on 26th August 1887, with an authorized capital of

£1,000,000 in shares of £5 each, of which over half was subscribed.

Sebastian de Ferranti was appointed Engineer and Electrician to the new company.

[...]

This wide area [along the whole north side of the Thames] was to be supplied

with electricity from a generating station located at Deptford on the South

Bank of the River Thames, about eight miles from the heart of London. The

output of the station was to be such that it would be capable of supplying

current for the electric lighting of the whole area at an unprecedented a.c.

transmission voltage of 10,000 volts. The location of the generating station

on the river, some distance from the town, had the advantage that at Deptford,

land was cheap, unlimited supplies of water were readily available, and sea-borne

coal could be obtained at low prices. There would be no noise from moving

machinery to disturb the slumbers of local residents, and no traffic congestion

occasioned by the carriage of coal through the streets to fuel the power station

boilers. For a parish of 200,000 lights, it was estimated that the fuel requirements

would necessitate the passage of some 200 cart-loads of coal each day.

Work on the proposed new power station at Deptford began during April 1888,

under Ferranti's direct supervision. [...]

The erection of the station was rapid, and in October 1888, the press were

invited down to view the progress made. [...]

The Electrical Engineer of 27th October 1888, commented: "On

Wednesday, the designer of the great Deptford installation was laughingly

dubbed the Michael Angelo of that installation, because from first to last,

from foundation to top of highest turret, architecture, materials, foundations,

and machines, all were specified or designed by one man, and the credit of

the success of the really first central station in England will have to be

given, without detracting one iota in favour of any other person, to Ferranti...

It required not only courage on the part of the engineer, but also a degree

of confidence that few men possess in earlier days of industrial development."

At the same time that work commenced on the building of the station, consideration

was given to the problem of transmitting power to the capital. Arrangements

were made with the railway companies (the London and Brighton; the London,

Chatham, and Dover; the Metropolitan; and the South Eastern) for permission

to carry the trunk mains along the parapets and bridges of the railways to

the distribution sub-stations in London. Six mains, or conductors, were to

be provided, two of which would be brought to Cannon Street, two to Blackfriars

Bridge, and two to Charing Cross. The use of railway property offered considerable

saving, in that it precluded an approach to each parish and vestry for permission

to excavate their roadways. [...]

Originally it was intended to transmit the power from Deptford to the Grosvenor

Gallery by means of jute insulated cables made by the Fowler Waring Company.

This was entirely satisfactory from an electrical point of view, but suffered

from the disadvantage that its inflammable nature, in close proximity to passing

steam locomotives, gave it a tendency to catch fire. Ferranti therefore decided

to use a type of mains that he had specified in his patent application of

1885.

This patent specification had described a complete distribution system for

electric lighting. Current from the generating station was to be transformed,

or converted as he termed it, down from the supply voltage to 100 volts for

supply to customers. The specification also details the type of mains to be

employed for the distribution:

"The mains for conveying the current I form of concentric tubes drawn

one over the other with insulating material between them."

The insulating material proposed was to be paper saturated with shellac in

solution. [...]

The proposal to make this simple concentric design of tubular main did not,

however, meet with Post Office approval. In a paper read before the Institution

of Electrical Engineers in 1889, W. H. Preece, the Chief Engineer to the Post

Office, said:

"It is quite certain that if a single conductor between Deptford and

London were subject to rapid alterations under a potential difference of 10,000

volts, the current returning by way of the earth, every telephone circuit

in the metropolis would be disturbed, and probably rendered unworkable."

Preece carried out a series of experiments with a lead sheathed concentric

cable, and found that when he used the sheath as a return for a.c. at a frequency

of 80 cycles/second, near the frequency of a Ferranti alternator, interference

in an adjacent telephone line resulted. When, however, he used the outer conductor

as the return, all was well. He came to the conclusion that an earthed sheath

placed over the concentric main reduced the electrical interference to negligable

proportions. Ferranti acted upon this information, and the following, well

known, construction of the Ferranti main resulted (Fig. 3.3).

A copper tube, 13/16 inch diameter and 20 ft long, was insualted with wax-impregnated

paper rolled on spirally, from sheets 20 ft in length and about 36 in. wide,

either by hand, or later by special machines which avoided straining the paper.

The sheets of paper were overlapped during application, until 0.5 in. of insulation

had been applied. THe outer conductor, of the same cross-sectional area as

the inner one, and 31/16 in. in diameter, was slipped over the insulated inner

conductor, and the combined assembly was drawn through a die in a heavy tube

drawbench, to compact the outer conductor down on to the paper insualtion.

A further 3/32 in. of waxed paper was then rolled on to the outer conductor,

and the whole enclosed in a thin iron tube of 2 3/8 in. diameter. The iron

pipe had a braised seam, and the space between the paper and the iron was

filled with hot bitumenous compound from a central injection point.

The jointing technique developed for these mains was of considerable importance.

Of necessity, joints had to be simple, as in the four seven-mile mains laid

between Deptford and the West End, there would have to be over 7000 of them.

It is believed that Ferranti got the idea for the joints (Fig. 3.4) from the

old wooden water mains, some of which are presevered in the Guildhall Museum,

and which consisted of logs with a male cone at one end which was fitted into

a female cone in the end of the next log, which in turn had a male cone at

its other end.

[...] Before bringing the ends of the main together, an iron sleeve was slipepd

over one length. This sleeve was so shaped as nearly to fit the protective

iron pipe, but elsewhere was somewhat larger in diameter, and in the enlarged

part a sleeve of prepared paper was placed. When the jointing of the outer

conductor was complete, it was wrapped with the prepared paper to bring the

diameter up to that of the iron pipe, the sleeve was moved into position,

and hot wax was forced in through a hole in the sleeve to displace air and

to fill up any spaces not occupied by the prepared paper. The ends of the

sleeve were fixed down to the protective pipe by corruguations applied by

a tool, and the hole through which the wax was introduced was closed by a

screw plug.

There was, of course, considerable criticism of the use of a voltage as high

as 10,000 votls with these mains, and doubts were cast upon their safety in

the event of a fault. Ferranti devised a demonstration to alleviate the doubts

and to convince even the most skeptical of their safety. Before a large number

of witnesses, Harold Kolle, Ferranti's personal assistant, held an un-insulated

cold chisel to the live main with his bare hands, while a colleague with a

slege hammer drove it through both conductors. As the chisel cut through the

main, the main fuse link cut off the supply without damage to the equipment

or injury to the very brave man involved. There is an apocryphal story that

Kolle, asked later if he had not been frightened, replied "Frightened?

I was scared out of my life. Young Henry had never used a sledge hammer before!".

[...]

Originally, it was intended to install twelve 10,000 horse-power generating

units, but the complete plans were partially forestalled by the operation

of the Electric Lighting Act of 1882, and the subsequent Board of Trade Enquiry

held in 1889. These, in effect, split up the area which was to have been supplied

from Deptford among a number of smaller companies.

On top of all this, the scheme was beset with a number of disconcerting and

almost disastrous incidents. One of the jointers was killed by a passing train

during the installation of the mains along the railway embankment. On another

occasion, one Joseph Selway was killed in the explosion at Stowage Wharf (the

site of the power station) on 9th April 1890. The accident occurred while

the works were being inspected by Major Marindin, who headed the Board of

Trade Enquiry; a steam pipe on one of the engines burst, and Selway was blown

28 ft by the explosion, and three other men were seriously injured.

A devastating fire occurred at the Grosvenor Gallery while it was being used

as a temporary sub-station. A power arc occurred during switching, which set

fire to the wooden roof before it could be extinguished. This resulted in

the complete destruction of the sub-station, and the loss of supply from the

15th November 1890, when the fire took place, until the following February.

During this period, a number of customers were lost, and there was no income,

only considerable expenditure. The opportunity was taken to push ahead with

what Ferranti referred to as "the permanent work" to an extent which

could not otherwise have been possible. The whole system of overhead lines

radiating from the Grosvenor Gallery were removed, and replaced by underground

cables.

The Board of the Electric Supply Corporation were not, however, very happy

with these misfortunes. They had lost a large amount of money, and as the

prospects of obtaining the virtual monopoly of the electricity supply for

London began to fade, sodid their confidence in their Chief Engineer. At the

meeting of the shareholders in March 1892, it was announced that during the

year, "the engagement of Mr. de Ferranti has ceased by the effluxion

of time".

Although this must have been a severe blow to Ferranti, particularly as he

had been accused by one member of the Board as being "sadly lacking in

prevision", he was now free to transfer elsewhere his experience, his

valuable patents, and his unrivalled knowledge of high voltage technique.

He did not have long to wait. The Directors of the newly formed British Insulated

Wire Company, having taken the opinion of Mr. W. H. Preece as to the value

of the Ferranti patents relating to electric cables, offered him a seat on

their board, acquired his patents, and insured his life for the sum of £20,000.

In retrospect, Deptford was a magnificent and daring enterprise. [...]

In the opinion of Colonel Crompton, "electricity supply owes far more

to Ferranti than to any other man. All the substantial features of supply

are founded on his work at the Grosvenor Gallery and at Deptford".

Electric Lighting Cables

[...] The view has been expressed that had the business of electricity supply

been destined to continue on the same limited scale as that of the earlier

undertakings, there is little doubt that the direct current system would have

been generally adopted.

One of the protagonists of the low voltage d.c. system was Thomas Alva Edison

(1847-1931), an inventor with Joseph Wilson Swan of the incandescent filament

lamp. Edison was very much aware of the dangers of high voltage electricity,

as at that time he was in his laboratory at Menlo Park, New Jersey, with other

workers in the field, considering the use of electricity in judicial execution.

During those years, the electrical press contained many references to this

work, as well as to the development of a 'secret death ray' which was reported

to have been applied to a flock of sheep with dire effect. The journals also

record the prolonged debate as a result of which the term 'electrocution'

entered the language, being thought a suitable word to describe the particular

electric shock treatment finally decided upon.

Edison, in a manner not unlike that of Ferranti around the same time, worked

out the details of a complete system for the distribution of electricity at

low voltage to customers. One problem encountered with low voltages was that

of 'copper loss' - the reduction of the supply voltage with the distance of

the customer from the generating station. As Edison determined to supply his

customers at 100 volts, it is said that he generated at 110 volts to ensure

the full voltage reaching the customer. The practice of an additional ten

percent has survived to the present day even though it is no longer necessary,

and is found in the voltage series of 11 kV, 22 kV, 33 kV, 66 kV, 132 kV,

etc. [...]

The mains which he proposed for the commercial distribution of electricity

were [...] to consist of two large segmental shaped copper rods (Fig. 4.1),

separated from each other by thick cardboard spacers strung together on a

jute string and contained in an iron pipe with a screw thread at each end.

This pipe was 20 ft in length and was subsequently filled with a bitumen compound

by means of a hand operated suction pump. These rigid mains were to be known

as 'Edison Tubes', and in a similar manner to the Ferranti mains detailed

a year or so later, and which only reached the stage of commercial application

in 1889, were of such a length that they could be transported around the average

street corner on a horse-drawn cart.

[...] The installation was started in January 1882, and a central generating

station erected in the basement of No. 57, Holburn Viaduct, the London offices

of the Edison Company. Mains in the form of Edison tubes were laid in subways

under the Viaduct to supply the street lights from Newgate Street to Holborn

Circuit, and numerous buildings along that route. [...]

In 1883, Edison adopted the three-wire d.c. system which had been introduced

[in] England in the previous year by Dr. John Hopkinson in Patent No. 3576

of 1882. [...]

In adopting the three-wire system, Edison had to modify the arrangement of

the conductors in his tube. These now took the form of three solid rods of

copper of the same circular cross-section, individually lapped with jute cord

in a very open lay (Fig. 4.2). Three such lapped conductors were then bound

together in trefoil formation by means of a fourth cord and the whole slipped

into the iron pipe. The bitumen compound was introduced as before. Special

joints were again designed to overcome expansion, to introduce right-angle

bends and to enable service cables to be connected.

[...]

Paper Insulated Cables

[...] Towards the end of 1892, a horizontal engine was acquired [by the British

Insulated Wire Company (B. I. Co.) ] from St. Helens, where it had been used

to grind pills. It was set to drive a Brush arc lighting machine. This was

to supply sixteen arc lamps mounted on special lamp standards, which were

erected chiefly at important corners of the town [Prescot]. These arc lamps

were in addition to the twenty 16-candle power incandescent filament lamps

which had been mounted in converted gas standards.

The engine and arc lighting machine were appropriately and inevitably named

"Joan of Arc", and were said to be a good deal more reliable than

either the circuits or the lamps which they supplied. It is recorded that

a man was appointed to go round the town after lighting-up time each night,

and to apply a vigorous kick to the base of any arc lamp standard in the event

of the lamp 'sticking'. [...]

In March 1892, all the four 10,000 volt Deptford mains were put out of commission

simultaneously by a fire which broke out in material stored beneath the arches

of the South Eastern Railway Company's viaduct near Spa Road, Bermondsey.

Despite the fact that the mains were carried along the parapet of the viaduct,

the fire was so intense that the exposed section of the mains was completely

destroyed. To prevent any similar accidents in the future, it was decided

to put this section of the mains underground.

By virtue of Sebastian Ferranti's influence with the London Electric Supply

Corporation, an order was placed with the B.I. Wire Company for the supply

of two 30-yard experimental lengths of 11,000 volt flexible, paper-insulated

concentric cable. These cables, when made, were the first flexible paper-insulated

cables to be employed at this voltage anywhere in the world. Their construction

followed the now familiar B.I. pattern; the inner conductors were made up

of 7/0.064 in. diameter wires, giving a nominal cross-sectional area of 0.0225